Welcome to PETROTECH ENGINEERS

Magnetic Level Gauge

Magnetic Level Gauge

Petrotech magnetic level gauges are highly accurate, low-maintenance alternatives to sight glasses and other outdated level indicators. They provide redundant, non-invasive level indication while eliminating leak points and fugitive emissions. Their robust design is ideal for high temperatures, high pressures and corrosive services. Petrotech gauges are easy to install and require no additional piping in most applications. Combined with externally mounted transmitters and switches, Petrotech magnetic level gauges provide the industry’s most advanced and cost-effective level solutions

- Feed water heaters ,Industrial boilers

- Oil/water separators, Gas chillers

- Flash drums, Surge tanks

- Deaerators, Blow down flash tanks

- Vacuum tower bottoms, Hot wells

- Alkylation units, Boiler drums

- Propane vessels, Storage tanks

- No process liquid in contact with indicator glass

- Upto 250 Bar Pressure

- Temperatures up to 400°C

- 360° magnetic coupling

- Float failure indication

- Full corrosion resistance system

- Remote Transmission Capability

- Permanent Local Indication without external power supply

- Switching and Transmitting options available

- Measurement is unaffected by pressure, vacuum, temperature, foam and Viscosity at design condition

- Minimum sensitivity to density variation

- Permanent local indication without external power supply

- Safe, environment friendly and trouble-free design

- Customized color options for flapper indicators

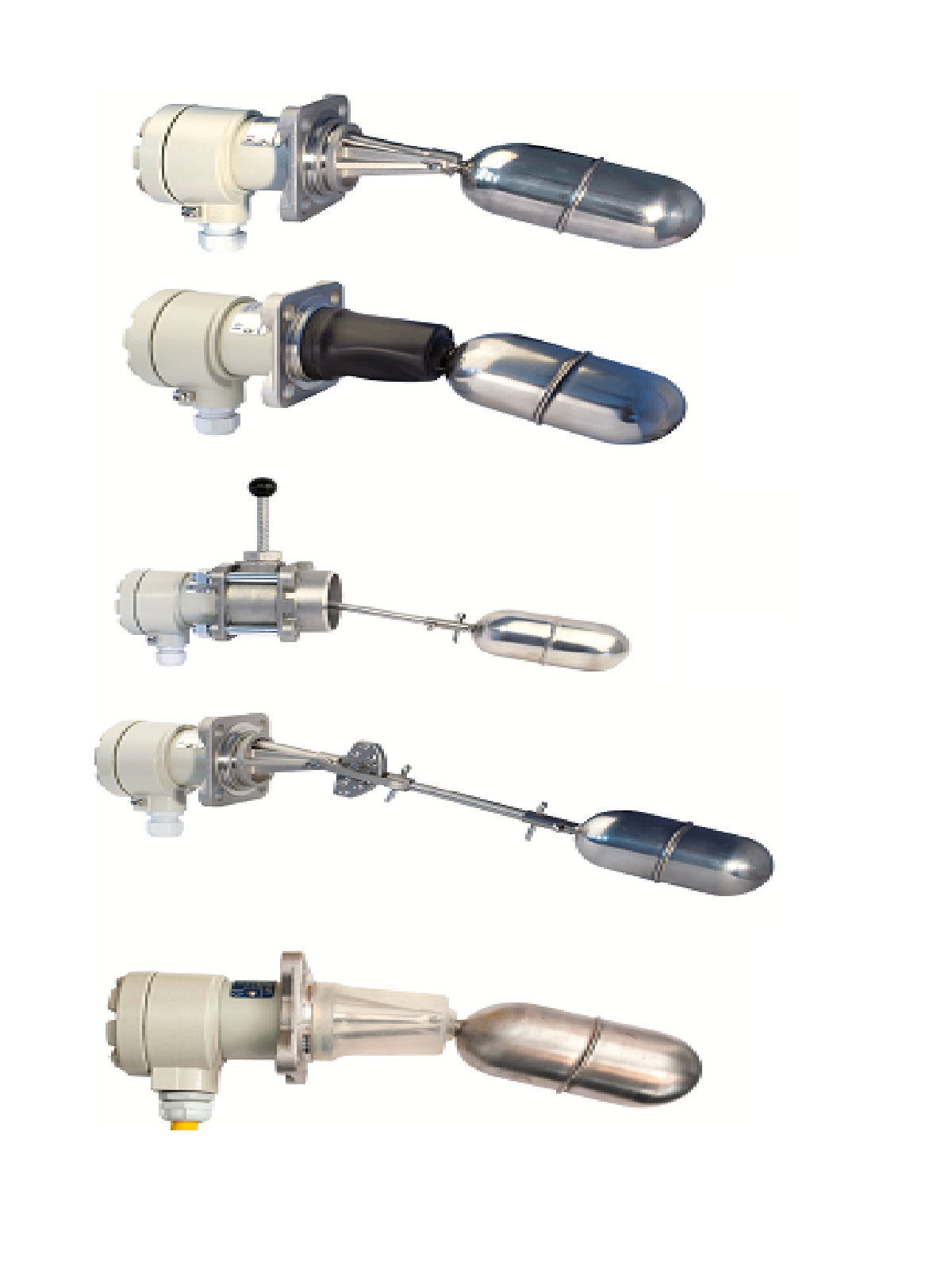

Side – Side

Top

| Installation | : Side/ Top |

|---|---|

| Range (C=C DIST) | : 300- 5000mm (Bicolor Flapper) 300- 3000mm (Follower Capsule) |

| Float Chamber | : 2” - 5” in SS304 / 316 / 316L , Hastealloy , Monel, Inconel, Titanium, PP, PVDF, PTFE lined SS chamber |

| Process Connection | : For Side Mounting- 25NB/40NB/50NB Flanges as per BS/ANSI/DIN or ½” / ¾” / 1” BSP/ NPT (M/F) Threaded For Top Mounting - 100NB Flanged to BS/ANSI/DIN |

| Float | : SS316, SS316L, Titanium, Hastealloy 276, Monel 400, PP, PVDF, PTFE |

| Level Indication Display | : a) PP Follower Capsule (Red) – 150°C (In Water Filled Glass Tube) b) PP Bicolor Flapper (Red- White) – 150°C c) SS Bicolor Flapper (Red- White) – 250°C d) Ceramic Bicolor Rollers (Red- White) – 400°C e) Plastic Bicolor Rollers (Red- White) – 150°C |

| Still Well (Top Mounted) | : SS304/SS316/SS316L/PP (80NB) |

| Calibrated Scale | : White Powder Coated Aluminium / SS304 (LC-10mm) |

| Shut off Valve | : 20 NB Ball / Globe Valve (SS), 25 NB Flange Ball Valve (PP) |

| Vent x Drain | : ½” Threaded Plugs / Valves |

| Max. Temperature | : 70°C (PP)/400C (SS and other Super Alloys) |

| Max. Operating Pressure | : Upto 250 Bar (Metallic Construction)/ Upto 2 Kg/cm2 (Plastic Construction) |

| Min. Liquid Sp.Gravity | : 0.4 - Side mounted, 0.8 - Top mounted. |

@2024 Petrotech Engineers. All rights reserved.